生産性と表面特性に役立つプラスチック添加剤は何ですか?

表面仕上げの一貫性、サイクルタイムの最適化、塗装または接着前の成形後作業の削減はすべて、プラスチック加工作業における重要な要素です。

プラスチック射出成形用離型剤複数の機能を持つものもあります。プラスチックの表面に留まり、プラスチックを潤滑するものもあります。シリコーン系離型剤シリコンを含まないものと比較して、優れた離型性を備えており、通常、サイクルタイムの長い製品の製造に有利です。

Silike Technology は、プラスチックおよびゴム製造業者向けにあらゆる種類のポリマー添加剤を提供することに尽力してきました…

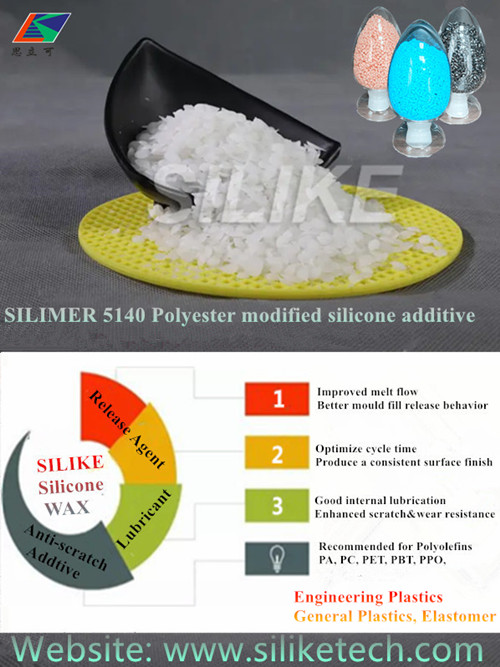

シリマー 5140は、一種のシリコンワックスポリエステルで改質されています。お客様から絶賛いただいていますシリコンワックスこれにより、エンジニアリングプラスチックの金型充填と離型性が向上します。シリコーン添加剤ほとんどの樹脂およびプラスチック製品との良好な適合性を有し、良好な耐摩耗性を維持します。シリコーン、それは素晴らしい内部潤滑剤、 離型剤、そして傷防止および耐摩耗剤プラスチック加工と表面品質に。

エンジニアリングプラスチックの添加が適切であれば、金型充填離型挙動の改善、内部潤滑の良好化、樹脂溶融体のレオロジー改善により加工性が向上します。また、傷や摩耗に対する耐性の向上、COF の低下、表面光沢の向上、ガラス繊維の濡れ性の向上、または繊維ブレーキの低下により表面品質が向上します。

シリマー5140金型の離型と、一貫した表面仕上げを生み出すサイクルタイムの最適化に重要な役割を果たします。

代表的な用途:

エンジニアリングプラスチック、一般プラスチック、エラストマー…

投稿日時: 2022年6月22日